Fabrication, Manufacturing, Reverse Engineering, and Retrofitting: What’s the Difference?

At APB, we specialize in a wide range of services, including fabrication, manufacturing, reverse engineering, and retrofitting. But what’s the difference between these four terms? And how can they help you overcome supply chain issues?

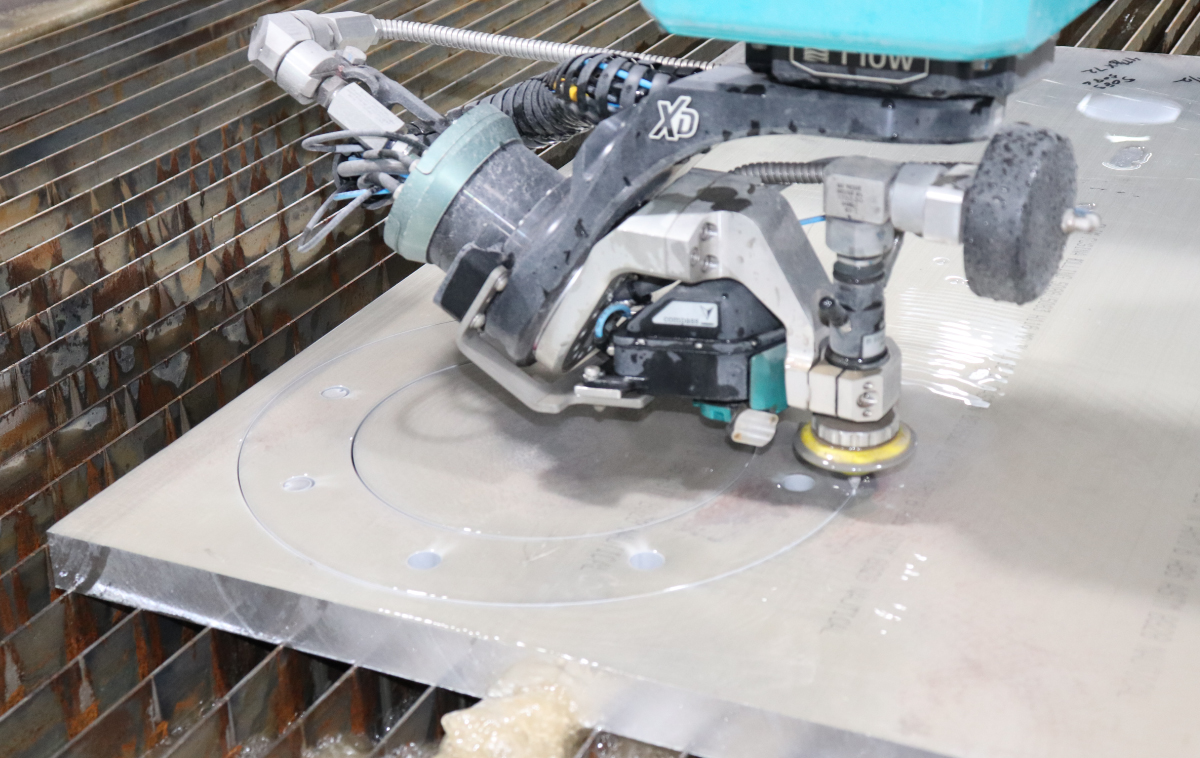

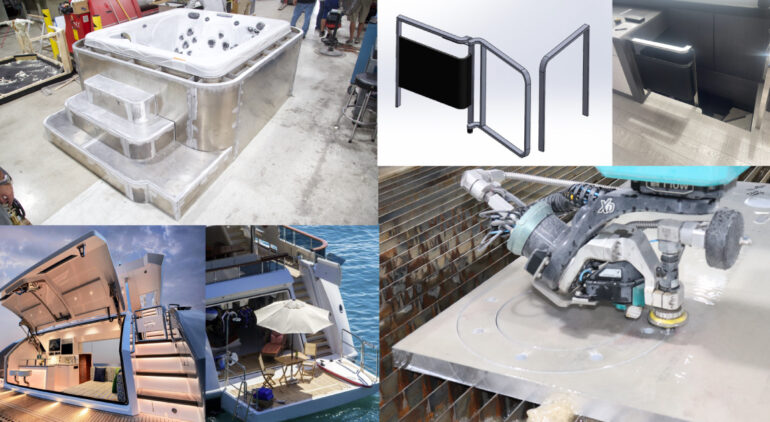

Fabrication is the process of creating parts or structures from raw materials. This can involve various processes, such as cutting, welding, bending, and forming. Fabrication is often used to create custom parts or products that are not available from mass-produced manufacturers. For example, if you want to install a custom-made stainless-steel railing on your boat for safety or aesthetics, a fabrication process would involve crafting the railing from raw stainless-steel materials, ensuring it perfectly fits your boat’s specifications.

Manufacturing is the process of creating products on a large scale. Utilizing cutting-edge technology, our metal manufacturing company excels in precision fabrication. We specialize in crafting high-quality metal components, ensuring durability and meeting industry standards. Trust us for reliable solutions tailored to your specific needs.

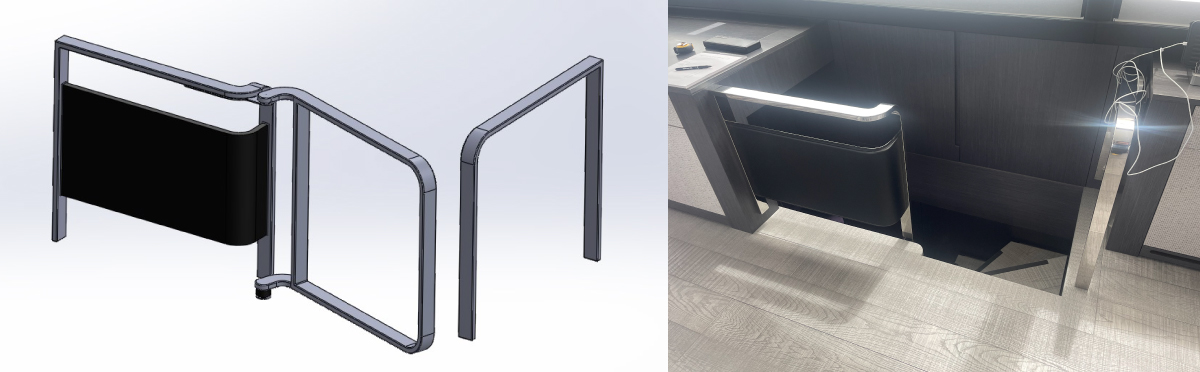

Reverse engineering is employed when there is a need to recreate or understand the design and functionality of existing boat components or systems, often without access to the original blueprints or specifications. This process involves disassembling, analyzing, and measuring existing parts to create detailed documentation that can be used for replication or improvement. Reverse engineering may be necessary when you want to recreate a specific part that is no longer in production or if you are looking to enhance the performance of an existing component. This method lets you gain insights into the original design and make necessary adjustments or improvements.

Retrofitting is the process of modifying an existing product to improve its performance or functionality. This can be done for various reasons, such as to comply with new regulations, extend the lifespan of the product, or add new features. A common and current yacht retrofit is on the swim platform. Due to more active and ambitious lifestyles while on the waters, yacht owners want to change the fixed space to serve more utility as a “beach” environment, such as housing smaller vessels for water recreation, adding pools, hot tubs, dining areas, and more to cater to a greater entertainment experience while aboard.

How APB Can Help You Overcome Supply Chain Issues

APB can overcome supply chain issues by providing all four services in-house. This means we can control the entire manufacturing process from start to finish. This gives us a significant advantage over companies that rely on outside suppliers for parts or components.

For example, if you are having trouble finding a replacement part for your boat, we can fabricate a new part for you. Or, if you need to modify your boat to comply with new regulations, we can retrofit it for you.

APB: Capabilities Beyond the Marine Industry

APB is not just a marine company. We also have the capabilities to provide fabrication, manufacturing, reverse engineering, and retrofitting services for a wide range of other industries, including (but not limited to):

- Aerospace

- Automotive

- Construction

- Energy

- Hospitality

- Industrial Equipment

- Medical / Pharmaceutical

- Military / Homeland Security / FEMA

- Transportation / Rail

No matter your industry, we can help you overcome supply chain issues and get the products and services you need.

If you are having trouble finding a supplier for your parts or components or need to modify an existing product, contact APB today. We can help you overcome supply chain issues and get the products and services you need on time and on budget.