APB 900 SW 21st Terrace Fort Lauderdale, FL 33312 | (954) 767-8255

- [email protected]

- (954) 767-8255

- 900 SW 21st Terrace, Fort Lauderdale, FL. 33312

Waterjet

Dynamic Cutting Head Technology

Home » Waterjet

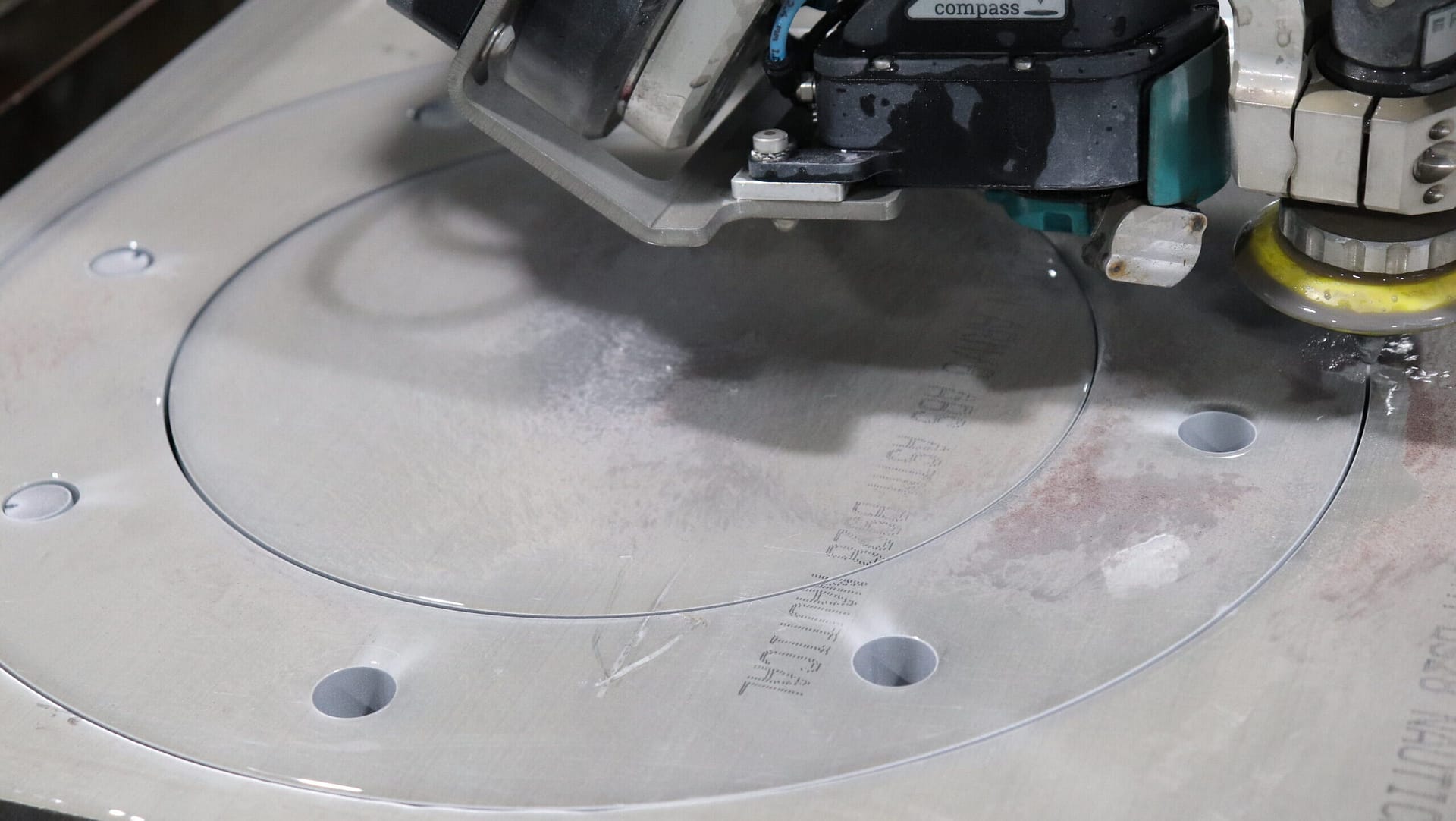

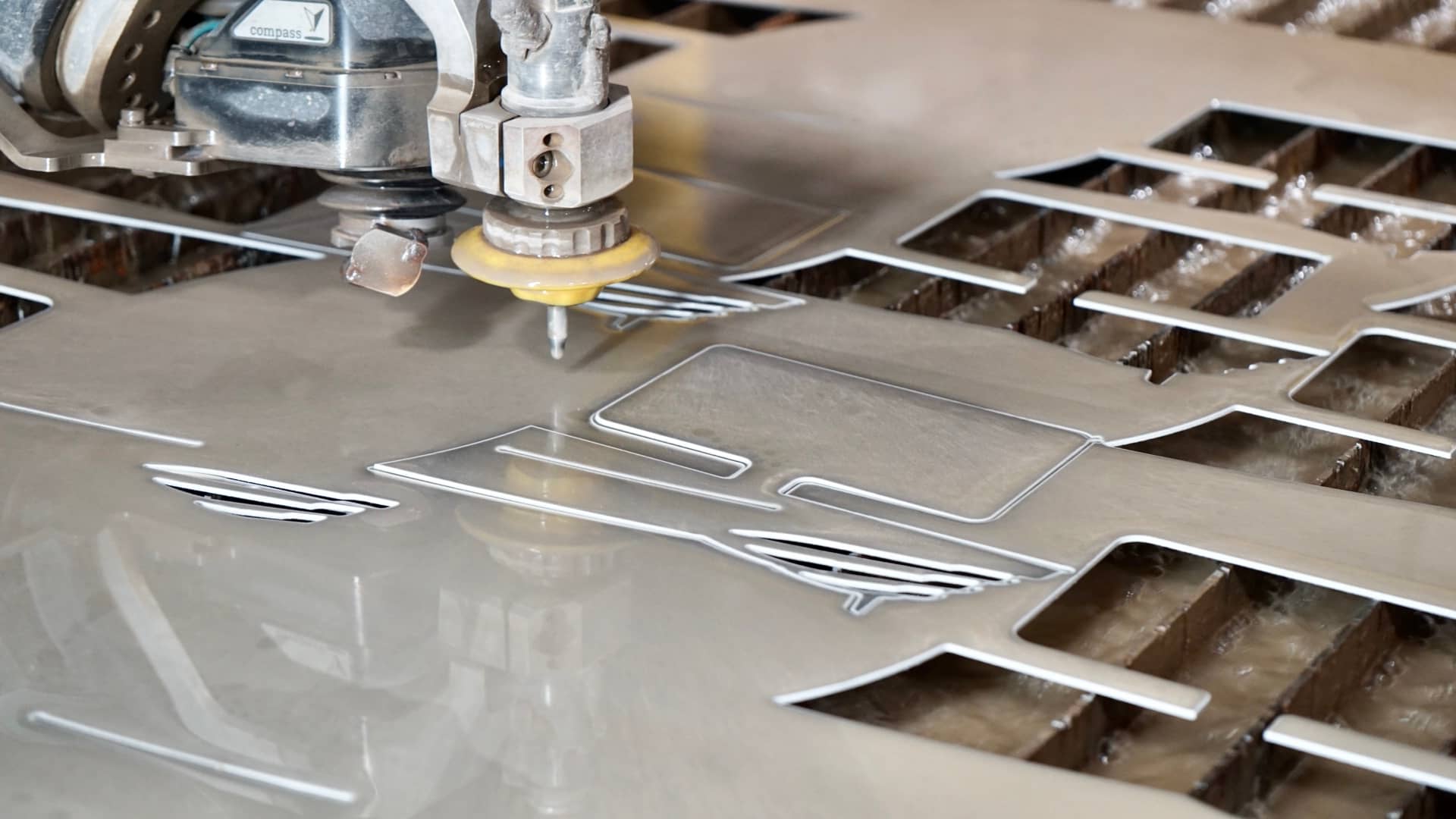

THE APB FLOW 500 WATERJET, BIGGER IS BETTER!

Our CNC Flow waterjet features a 10’x20’ 5-axis with 3D cutting and has the largest size cutting footprint in Florida. With its 94,000psi pump this waterjet gives APB the unique capability to increase cutting speed dramatically. This advantage in speed translates into lower pricing and higher production figures for our manufacturing clients.

SPECIFICATIONS

- Variety of edge qualities and tolerances, up to +/- .006″

- Dynamic cutting head technology – Zero edge taper / kerf even faster cut speeds; provided as APB standard cut quality

- Material thickness (8″) regardless of material type

- Complex radial geomatry, chamfering and beveling

- Ultra high pressure 94,000psi – 25% faster cutting times than traditional waterjets for increased productivity and pricing economies

MATERIALS

- Titanium

- Stainless Steel

- Carbon Steel

- Copper

- CuNi

- Composites

- Plastics

- PVC

- Rubber

- Acrylics

- Plexiglass

QUALIFIED ENGINEERING DEPARTMENT

- APB’s in-house engineering department, product design capabilites & nesting services are performed.

- Latest 3D modeling software with design and flow analysis capabillities.

- CNC programing & design

THE APB FLOW 500 WATERJET, BIGGER IS BETTER!

Our CNC Flow waterjet features a 10’x20’ 5-axis with 3D cutting and has the largest size cutting footprint in Florida. With its 94,000psi pump this waterjet gives APB the unique capability to increase cutting speed dramatically. This advantage in speed translates into lower pricing and higher production figures for our manufacturing clients.

SPECIFICATIONS

- Variety of edge qualities and tolerances, up to +/- .006″

- Dynamic cutting head technology – Zero edge taper / kerf even faster cut speeds; provided as APB standard cut quality

- Material thickness (8″) regardless of material type

- Complex radial geomatry, chamfering and beveling

- Ultra high pressure 94,000psi – 25% faster cutting times than traditional waterjets for increased productivity and pricing economies

MATERIALS

- Titanium

- Stainless Steel

- Carbon Steel

- Copper

- CuNi

- Composites

- Plastics

- PVC

- Rubber

- Acrylics

- Plexiglass

QUALIFIED ENGINEERING DEPARTMENT

- APB’s in-house engineering department, product design capabilites & nesting services are performed.

- Latest 3D modeling software with design and flow analysis capabillities.

- CNC programing & design