A Quick Guide to Material and Gases Used in Marine Welding

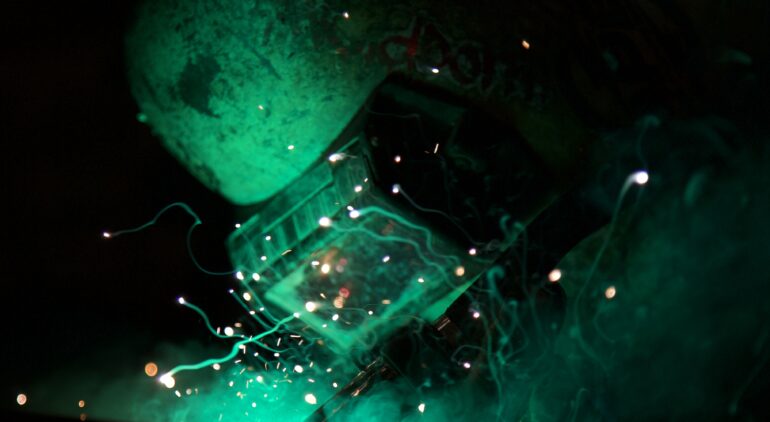

Marine welding plays a vital role in shipbuilding. It impacts the overall performance of welded components in a marine environment. The material used in welding influences the outcome of marine welding, thus ensuring the integrity and reliability of welded objects. In this article, we’ll explore the different types of metals and gases used in marine welding by welders and fabricators, as well as about their properties, applications, and considerations. Check out the below points for further information-:

1. Metals Used in Marine Welding:

- Carbon Steel:

Carbon steel is known for its high strength and durability. The most sought-after reason to use carbon steel in marine welding is it can bear various stresses like waves, winds, and dynamic loads. However, it is susceptible to corrosion and requires a protective coating or alloying with corrosion-resistant element.

- Stainless Steel:

Exposure to saltwater is a major concern as it can corrode the material. Stainless steel is known for its corrosion resistance and durability. Hence, it is an apt material to use in marine welding. Partnering with experienced stainless steel fabricators in Fort Lauderdale can ensure that the fabricated structures or components are built to withstand the harsh marine environment.

- Aluminum Alloys:

Aluminum alloy is another corrosion-resistant material used for marine Aluminum fabrication and welding near you. The light-weight of aluminum is another property that makes it suitable for marine applications. It is frequently used in the construction of boats, ship decks, and superstructures.

- Nickel Alloys:

Nickel alloys are commonly used in propellers and valves. It exhibits excellent corrosion resistance, even in harsh marine conditions. The melting point of nickel alloy is high, which is why it is suitable for making parts of marine objects that have high exposure.

- Copper-Nickel (CuNi) Alloys:

Copper-Nickle (CuNi) Alloy is often used in the construction of ship hulls and piping systems. It is known for its resistance to biofouling and corrosion.

2. Gases Used in Marine Welding:

- Shielding Gases:

Argon and helium are commonly used to create a protective atmosphere during welding. It protects the molten weld pool from atmospheric contamination, reducing the risk of defects.

- Flux Gases:

Carbon dioxide and mixtures containing CO2 are used as flux gases. It facilitates the removal of impurities and enhances the stability of the welding process.

- Cutting Gases

Oxygen and acetylene are frequently employed for cutting and welding applications. It is essential for processes like flame cutting and oxy-fuel welding.

Ending Note

Marine welding is mostly about carefully selecting metals and gases for a successful shipbuilding and repair project. Engineers and welders must consider factors such as corrosion resistance, strength, and regulatory compliance to create maritime structures that can withstand the harsh conditions of the open sea. In addition, it is also important to choose class-certified professionals; for marine welding, you can look for ABS, Lloyd’s Registrar, and RINA certifications. The properties and application of various metals and gasses ensure the longevity of marine welds, hence contributing to the integrity and safety of the vessel.